Hardware Prototyping Tools & Methods

| ✅ Paper Type: Free Essay | ✅ Subject: Technology |

| ✅ Wordcount: 2629 words | ✅ Published: 23 Sep 2019 |

Hardware Prototyping Tools & Methods

(SEP – 757)

Case Study– 1

1.The significance of the TED talk

Joseph Di Simone discussed the new technology in 3D printing (CLIP), there is a possibility that it might completely replace the current manufacturing techniques and can bring whole new possibilities in the field of manufacturing. Objects with very complex geometries, which cannot be injection molded or manufactured by milling can be easily manufactured by traditional 3D printers. Regardless of the benefits of 3D printing over conventional manufacturing methods, it is only considered as a prototyping technology.

1.2 The major drawbacks that hold existing 3D printing from being a manufacturing process:

● It consumes more time as compared to conventional manufacturing techniques

● 3D Printed parts show anisotropic behavior (Physical properties varies when measured in different directions) [6]

● The surface finish of 3D printed parts is more as compared conventional manufacturing techniques

● Limited choice of material

This new technique CLIP would eliminate the above-listed limitations in 3D printing. CLIP has the potential to revolutionize the whole manufacturing industry and it is much faster, reliable and better than traditional 3D printing technique. This technology opens the wholes new possibilities for future designers and engineers.

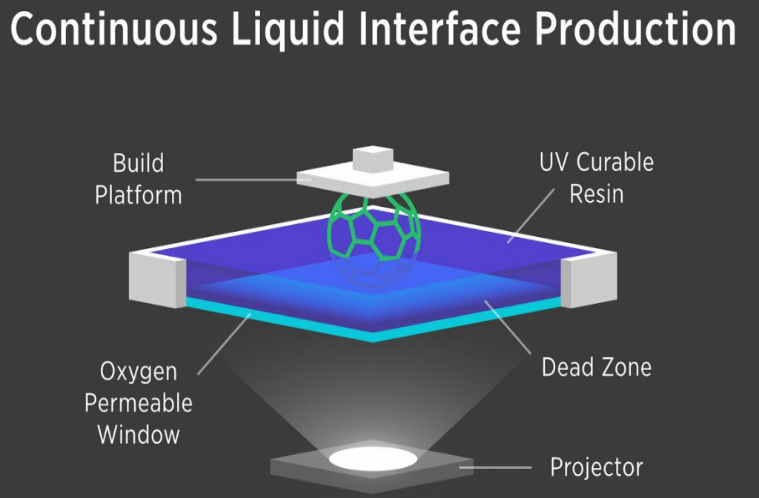

1.3 CLIP (Continuous Liquid Interface Production)

It is a photochemical process which pulls out a solid workpiece from a molten pool of a plastic material. It is based on the stereolithography process in which light and oxygen are used to grow parts from a pool of resin.

1.4 Major functional components of CLIP setup:

|

Component |

Function |

|

Reservoir |

Holds the UV Curable Resin |

|

Build Platform |

Pulls out the object out of the liquid pool |

|

Digital light Projector |

Acts as a source of light |

|

Window |

Allows light and oxygen to pass through it |

1.5 Working:

The Build Platform is lowered into the resin pool and with oxygen and UV light coming through the window, the reaction gets inhibited. Then, the object starts growing, and build platform pulls the object up. [Figure: 1]

1.6 Difference between CLIP and FDM/SLA

|

Traditional 3D Printing Techniques (FDM/SLA) |

Continuous Liquid Interface Production (CLIP) |

|

Traditional 3D Printing is slow as compared to CLIP |

CLIP is 25 to 100 times faster than traditional 3D printing |

|

Mechanical properties show Anisotropic behavior |

Mechanical properties show Isotropic behavior |

|

The tendency to have more defects due to melting and solidification of layers. |

Objects manufactured with CLIP have fewer defects, They Show properties like injection molded objects. |

|

Surfaces made by these techniques are generally rough due staircase defect |

Smoother Surfaces can be obtained because they do not depend on the orientation of the print direction |

|

Objects manufactured with traditional 3D printing techniques have low resolution compared to CLIP |

Objects can manufacture in mesoscale with this technology i.e. 10 microns to 100 microns |

1.7 The most critical differences and why are they significant for the future of additive manufacturing

Additive Manufacturing is only considered as a Prototyping tool because it sometimes takes days to manufacture an object. CLIP can manufacture 25 to 100 times faster than traditional 3D printing. CLIP technology has the potential to bridge the gap between prototyping and manufacturing and can start a new era of 3D manufacturing.

CLIP technology gives us the choice of achieving desired material properties by changing the chemistry of the resin, that was not possible in objects printed using traditional techniques. By using CLIP, we are now able to manufacture the Elastomers (they have high elastic strength and vibration damping properties), complex geometries and objects with high strength to weight ratio. This opens the possibility of using additive manufacturing in fields like automotive and aerospace industries. 3D printed objects using traditional techniques do not give us desired end material properties that’s why they are only used for rapid prototyping, but by using the CLIP we can now obtain desired material properties and probably use 3D printing in manufacturing.

1.8 How can companies utilize this technology?

- Health sector and dentistry can utilize this technology in making parts in real times in an emergency according to one’s own anatomy.

- CLIP can also be used in microfabrication. Subtractive manufacturing techniques are not suitable to manufacture objects in mesoscale. By using CLIP, we can manufacture objects ranging from 10 microns to 1000 microns.

2. Key aspects of ‘AEB White Paper ‘Six theories about how 3D printing will change logistics’:

3D printing is an emerging technology. Nowadays, more and more sectors have started using this technology. It is certain that the market share of this technology will continue to grow. This article puts forward theories, how this technology is going to affect society and particularly logistics.

Till recent times, 3D printing was used for building prototypes by automotive and aerospace industries along with the medical industry which uses it for building replacement parts. Researchers believe that in upcoming 20 or 50 years, it would be possible to have mobile production platforms using which components could be printed right away where they are needed eliminating the need for transportation.

2.1 Benefits of 3D printing stated in the article:

- Less wastage of material because of the layer by layer deposition of material, while in traditional manufacturing a lot of material gets wasted due to the subtractive nature of the process.

- It is possible to manufacture light and stable 3D printed structures with any possible geometric form. For example, hollow and honeycomb structures.

- 3D printing allows to produce customized products, the design is adaptable and can be made to according to order.

- 3D printing enables decentralized production, the product can be printed near to customer, it will eliminate the cost of transportation

- 3D printing can be used for batch production and limited mass production

- 3D printing makes it possible to manufacture light weight components for the aerospace and automotive industries. When these components will be installed, they will reduce CO2 emissions.

- The design of the component can be easily improved or modified in 3D printing

- We can make replacement parts on demand rather than storing them.

- 3D printing can possibly bring back manufacturing to countries with high wages

- Electronic transactions will eliminate customs duties.

2.3 Limitations and challenges of 3D printing discussed in the article:

- 3D printing is not yet suitable for mass production

- Most of the 3D printing techniques produce rough surfaces

- If we consider the possibility, that 3D printed parts designs are electronically transferred by bypassing customs, they no longer be passed from safety controls.

- If anyone with the 3D printer will become Manufacturer, then who will be liable for any miss happening

- If anyone can download blueprints from the internet, then Intellectual property issues will arise

2.4 Theories about ‘how 3D printing will change logistics’ mentioned in the paper:

First Theory – 3D printing will offer opportunities for mass customization and decentralized production.

3D printing will provide an opportunity to design and customize products according to one’s personal requirements, for example, personalized coffee mugs, door knobs or towel racks Decentralized productions plants will be setup that will reduce transportation cost. Industries will bring back their manufacturing plants back to high-wage countries. Mass production in East Asia will decline and it will also affect long-distance shipping.

Second Theory – Last-mile shipping will increase.

Goods will no longer be shipped around the world. Because we will print them printing station near to customer. Moreover, it will not eliminate transportation. We still have to transport raw materials and 3D print cartridges. This will increase local printing facilities near to customer market. That will increase “Last-Mile” shipping

Third Theory – The market for 3D desktop printers will continue to grow

The number of people that will use 3D printers will increase in the future. Designs can be easily downloaded from the internet or can be created using mobile applications. A person can easily take their design to a 3D printing shop and get it printed. The number of these 3D printing shops is going to increase in major cities in the coming years.

Fourth Theory – 3D printing will make the world a little bit greener

The four ways in which 3D printing can make the world green:

- By using 3D printed lighter parts in the aerospace industry, it will reduce the weight of the whole aircraft while will eventually decrease the fuel consumption and lower the CO2 emissions.

- 3D printing consumes a lot less material as compared to Subtractive manufacturing techniques.

- Printing parts in local stations will eliminate the long-distance shipping will result in less CO2 emissions.

- There will be no longer a need for keeping replacement parts in stock. They can be replaced by blueprints that will save resources.

Fifth Theory – Replacement parts will be stored as data models in Virtual warehouses and printed on demand

As mentioned in the fourth theory replacement parts could be stored in databases and printed on demand thereby reducing the need for storing parts.

Sixth Theory – Customs authorities will lose their oversight role

With the increase of circulation of digital blueprints globally, physical border and imports duties will be bypassed. This will affect revenue generation from the import duties.

3. Key aspects of ‘Opinion: Paris 2017 And the Future of Additive Manufacturing’:

This article gives an overview of advancements in Additive Manufacturing. Bionic designs (Idea of incorporating designs found in nature) and advanced fabricated methods are the future of Additive manufacturing.

General Electric leader in the field of Additive Manufacturing, used Additive manufacturing for making fuel nozzles. They are also planning to print 35% of their new turboprop engine using 3D printing. GE is also developing the world’s largest 3D printer.

The focus of additive manufacturing industries has been shifted from making small and complicated shapes to make large structural parts. More and more 3D printing facilities are opening globally. AM fabrication machines are advancing, and AM powder is also becoming cheaper.

Regardless of all the benefits of AM fabricated parts in the aviation Industry, economics and regulations remain a major barrier to the adoption of this technique. But it is evident that we will see AM empowered designs in the future.

4. Future of Additive Manufacturing

Additive Manufacturing has many advantages over subtractive. Although it will dominate the manufacturing industry in the future. But, according to me, it will not eliminate traditional manufacturing techniques completely. Probably we will see hybrid 3D printing machines in the future, for example, a combination of the drilling machine and a 3D printer.

With 3D printers are now able to print bionic designs and companies like GE Aviation and Boeing are investing to make improvements in these technologies. Mr. Joseph also discussed in the TED talk that technology like CLIP has the potential to print up to 1000 times faster than traditional 3d printers.

By considering the facts that are mentioned above additive manufacturing will going to become a major technique of manufacturing in the future. Additive printing will be adopted by most of the sectors Like Automotive, Aviation, Food Industry, Construction Companies, and Sports manufacturers etc.

3D printing was initially developed as a prototyping tool, but it will become a significant instrument for manufacturing. With an introduction of technologies like CLIP now we can manufacture 100 times faster than tradition 3D printing and the wastage of material in this technique is much less when we compare this with subtractive manufacturing. Due to these advantages of 3D printing over traditional manufacturing techniques, we are going to see the whole new era of 3D Manufacturing. I believe that rather that using 3D printed parts in end products, in future we will see full objects manufactured using 3D printing, for example, whole aircraft made with Additive Manufacturing.

Each sector is investing in 3D printing, from NASA to the food industry, everyone is experimenting with 3D printing techniques. Someone has put forward the concept of food printing. [10] A prototype of a pizza printing machine has already been tested [Figure: 2]. By seeing all these advances, I believe that our daily lives will be surrounded by 3D printers. For example, food printers, utensil printers, shoe Printers, electronic device printers or even automobile printers.

5. An institution that utilizes AM at a larger scale, for end-use products

General Electric – General Electric is using 3D printers for making fuel nozzles for the new Leap jet engines.

Boeing – The airline company has made more than 20,000 3D printed parts for different military and commercial planes.

Ford –Ford made engine covers for the 2015 Ford Mustang with 3D printers. Ford has been using Additive manufacturing for printing auto parts since the 1980s and they recently printed their 500,000 part with a 3d printer which was an engine cover for Ford Mustang. [Figure: 3]

3D Systems Sugar Lab – The company printed a 3D printed edible model of Ford Mustang.

Nike – The footwear company used 3D printing technology to make Cleats for the 2014 Super Bowl.

American Pearl – The jewelry company uses 3D printing technology to make a customized piece of jewelry by choosing specific metals, gems, and diamonds. Customers can design their products online and get them 3D printed

Hasbro –Hasbro a toy manufacturing company uses 3D printing technology to manufacture toys. They also filed a patient for a kids-oriented 3D printer, in which kids can print their own toys. [9]

MakieLab –MakieLab Company allows the user to make their own 3D printed customized doll (Makie Doll). Customers will be able to choose all the features of the doll such as facial expressions, smile, jaw, and hairs etc. MakieLab also prints other games and toys but Makie Doll is their most popular product.

Royal Dutch Shell –The company uses 3D printing technology to manufacture metal parts such as metal connectors that are used for drilling and refinery operations. [10]

Figures

[1] Saunders, S. (2018, September 18). Continuous Liquid Interface Production (CLIP) technology [Digital image]. Retrieved February 8, 2019, from https://3dprint.com/wp-content/uploads/2015/03/dia.png

Figure 1: Typical Setup of CLIP

[2] 3D printed pizza [Digital image]. (2017, May 1). Retrieved February 8, 2019, from https://www.manufacturingtomorrow.com/images/upload/images/image03(13).jpg

Figure 2: 3D Printed Pizza

[3] Gilpin, Lyndsey. “Ford Made Engine Covers for the 2015 Ford Mustang with 3D Printers.” TechRepublic, 26 Mar. 2014, www.techrepublic.com/article/3d-printing-10-companies-using-it-in-ground-breaking-ways/

Figure 3: 3D printed cover for the 2015 Ford Mustang

References

[1] Kaartinen, H., Koyhajoki, T., Wenngren, J., & Bjork, E. (2018). Utilizing 3D printing in manufacturing companies: Comparative demonstration in a company case. 2018 2nd International Symposium on Small-Scale Intelligent Manufacturing Systems (SIMS).doi:10.1109/sims.2018.8355306.

[2] Michaels, K. (2017). Opinion: Paris 2017 And The Future Of Additive Manufacturing. Aviation Week & Space Technology. Retrieved February 8, 2019.

[3] AEB White Paper: Six theories about how 3D printing will change logistics. (n.d.). AEB. Retrieved February 8, 2019.

[4] Petrovic, V., Gonzalez, J. V., Ferrando, O. J., Gordillo, J. D., Puchades, J. R., & Griñan, L. P. (2010). Additive layered manufacturing: Sectors of industrial application shown through case studies. International Journal of Production Research,49(4), 1061-1079. Retrieved February 8, 2019, from https://www.tandfonline.com/doi/abs/10.1080/00207540903479786

[5] Types of 3D printers or 3D printing technologies overview. (2016, February 02). Retrieved February 8, 2019, from http://3dprintingfromscratch.com/common/types-of-3d-printers-or-3d-printing-technologies-overview/

[6] New Technology Transforms 3D Printing. (n.d.). Retrieved February 8, 2019, from https://www.asme.org/engineering-topics/articles/manufacturing-design/new-clip-technology-transforms-3d-printing

[7] Gilpin, L. (n.d.). 3D printing: 10 companies using it in ground-breaking ways. Retrieved February 8, 2019, from https://www.techrepublic.com/article/3d-printing-10-companies-using-it-in-ground-breaking-ways/

[8] Borison, R. (2014, September 02). All The Ways Your Kids Can Now Customize Their Toys. Retrieved February 8, 2019, from https://www.businessinsider.com/3d-printing-toys-2014-8

[9] Three Major Companies That Already Use 3D Printing. (2018, April 19). Retrieved February 8, 2019, from http://me3d.com.au/2018/three-major-companies-3d-printing/

[10] More Advanced Manufacturing and Factory Automation Resources. (n.d.). Retrieved February 8, 2019, from https://www.manufacturingtomorrow.com/article/2017/01/3d-printing-from-prototype-to-production/8964/

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal